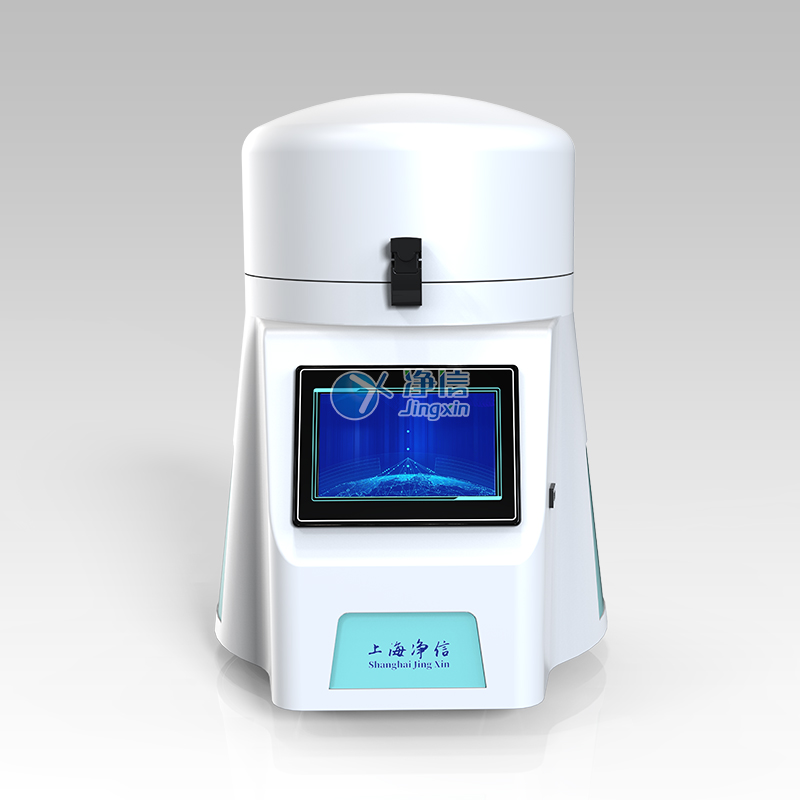

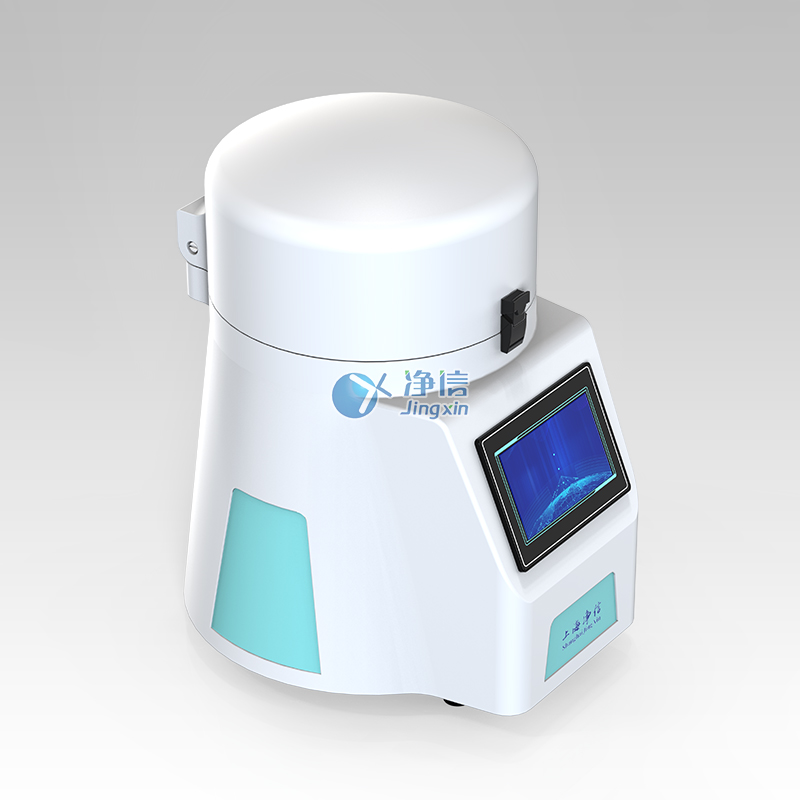

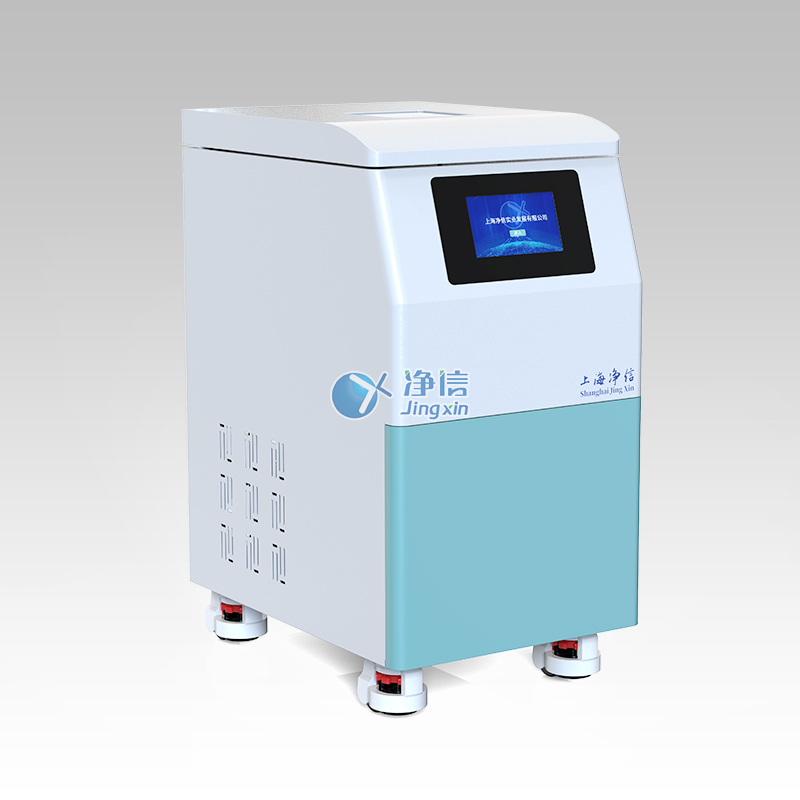

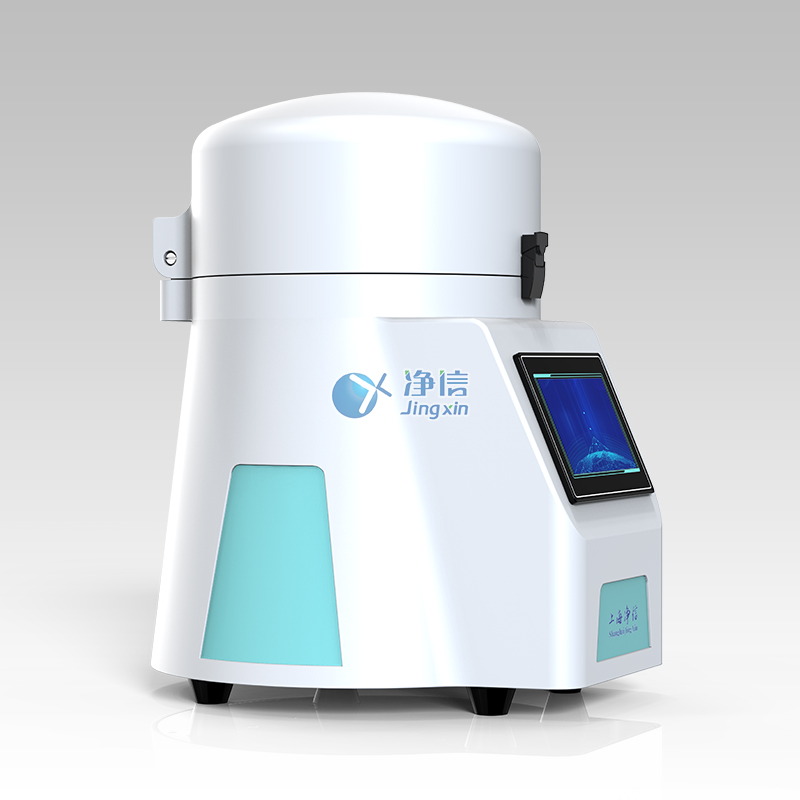

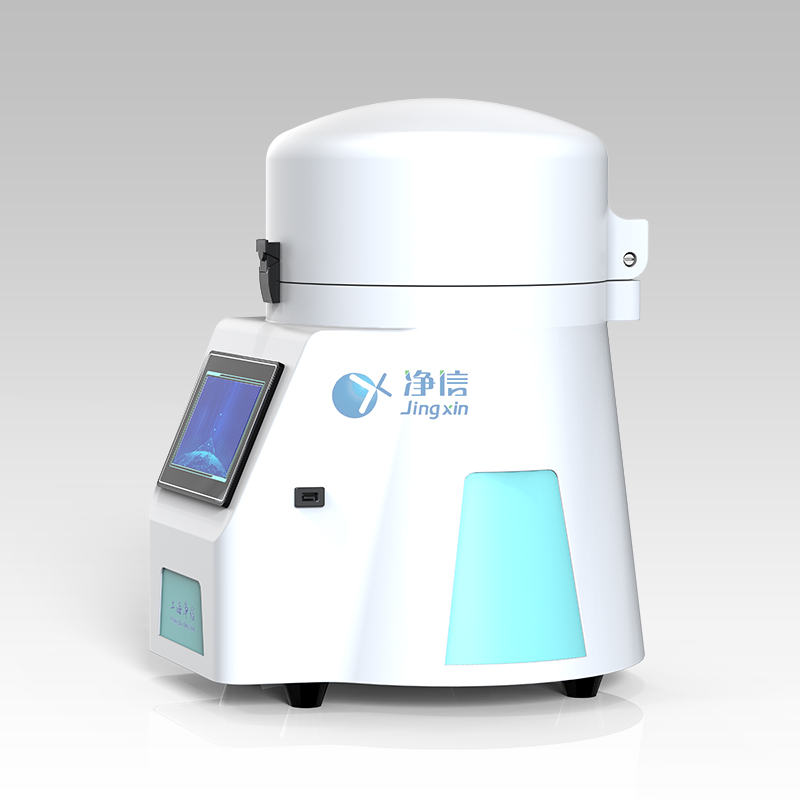

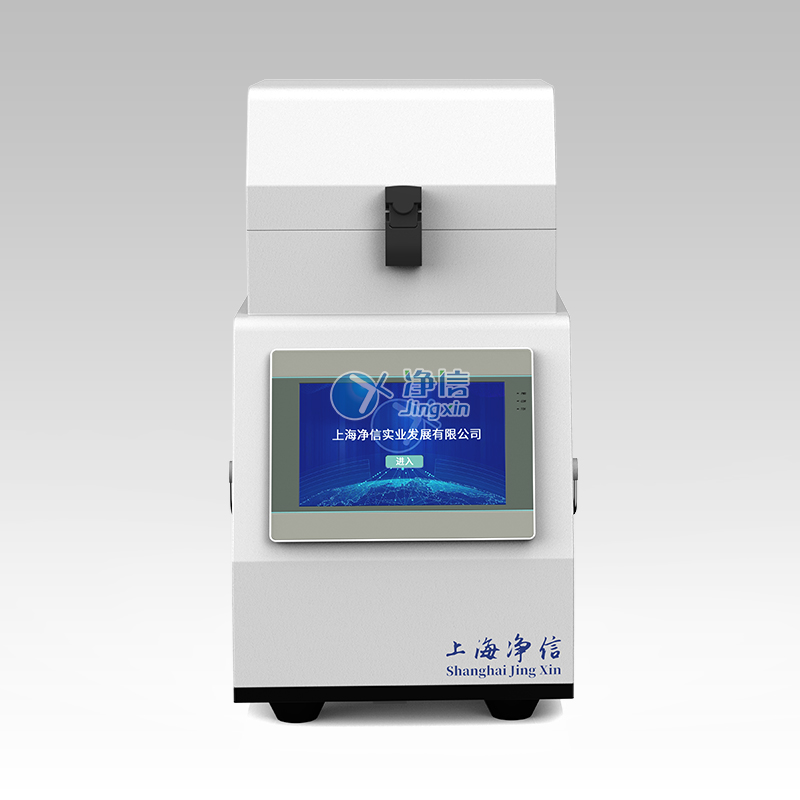

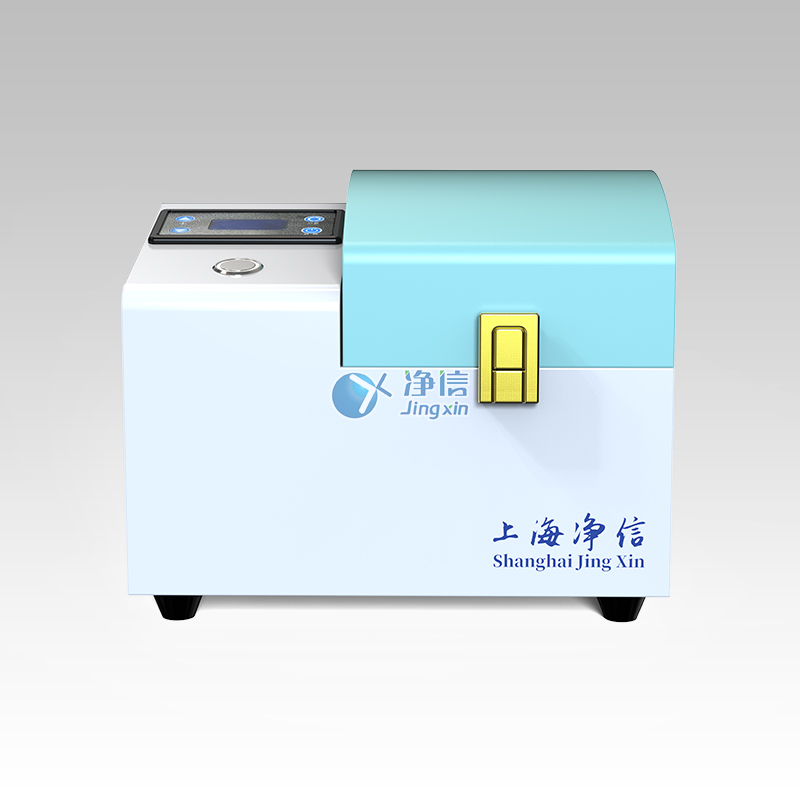

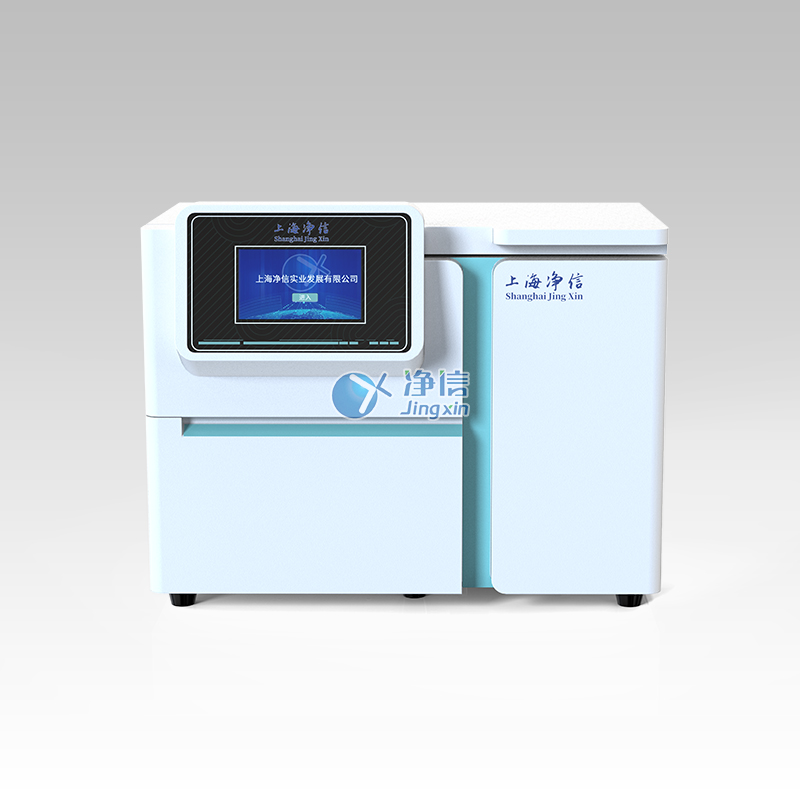

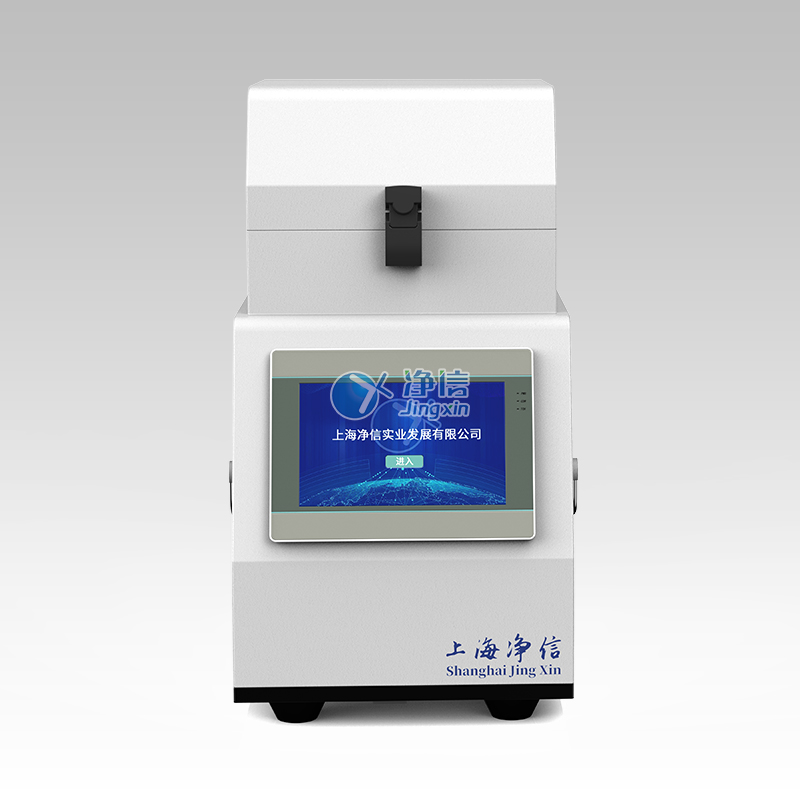

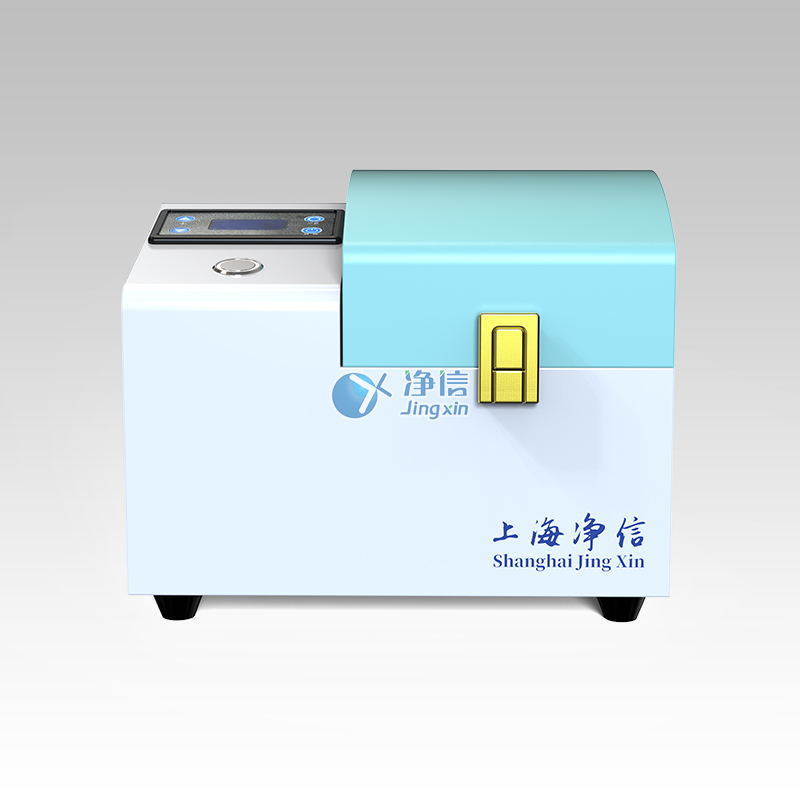

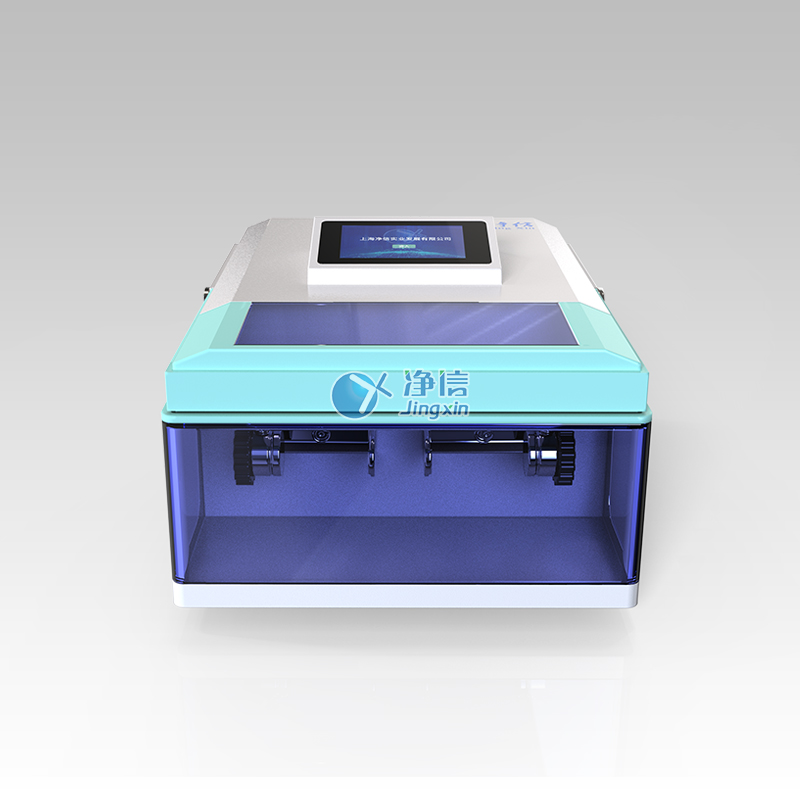

The all-round planetary ball mill produced by Shanghai Jingxin Company is suitable for wet and dry pulverization and refinement of hard, medium hardness, brittle and fibrous materials. The sample size can be less than 100nm, and it can also be used for solids in suspension. The grinding, sample mixing and homogenization treatment and metal alloying can achieve perfect and outstanding results. The sample processing capacity is 12000ml, and 4 ball mill jars with a volume of 3000ml can be placed at the same time. There are more than ten kinds of ball mill jar materials to choose from. Use innovative gear noise reduction technology and fully enclosed noise isolation design to control operating noise, effectively improve the comfort of laboratory use, high-efficiency sample processing capabilities, unique appearance and structure design, and strict production process assistance. Shanghai Jingxin JXFSTPRP has become one of the most popular sample preparation products for users.

Application samples:

*Medicinal materials: ginseng, dendrobium officinale, tablets, medicine, licorice

*Biological samples: plant raw materials, bones, tobacco, pearls

*Inorganic substances: glass, iron powder, aluminum powder, magnesium powder, ceramics, alumina, metal oxides, alloys, graphite

*Inorganic substances: coke, coal, ink, cellulose, carbon fiber, sewage sludge, wood

*Ores: iron ore, kaolin, limestone, gypsum, quartz, minerals, ore, clay minerals, soil, cement slag, concrete, slag

*Others: paper, chips, polymers, pigments, fiber products, catalysts, chemicals, waste samples

working principle:

Under the effect of the geometric structure of the grinding carrier and the special movement mode, the high-frequency and high-intensity collision, shear and friction between the grinding medium and the sample directly make the sample achieve an extremely excellent grinding effect and have a fast processing speed. The sample size is small, uniform and consistent.

In the use of the planetary ball mill, the sample processing needs to be carried out in the ball mill carrier through the action of the grinding medium. Therefore, the ball mill carrier and the ball mill medium are indispensable and the main accessories of the planetary ball mill. The ball mill carrier and ball mill developed by Furkas There are more than ten different materials for the medium to be combined for selection, and different treatment effects can be achieved when processing samples with different physical and chemical properties.

Performance parameters:

Main parameters | Parameter range |

Brand Name: | JXFSTPRP Jingxin |

Product name: | High Energy Grinding Machine |

Model: | JX-5G |

Injection size (different materials): | < 10mm |

Sample size: | < 100nm |

Processing capacity: | 50ml/罐 |

Processing capacity: | 4x3000ml |

Main disc speed: | 35-335r/min |

Rotation speed of ball mill tank: | 70-670r/min |

Transmission ratio (planetary disc/ball mill tank): | 1:2 |

Forward and reverse operation: | Yes |

Dangerous emergency stop: | Yes |

Grinding room lighting description: | LED light source, automatic switch, 220V, 18W |

Ball mill carrier material: | stainless steel (304/316), tungsten carbide (WC), nylon (MC), polyurethane (PU), polytetrafluoroethylene (PTFE), poly handle burning tank (PP), nylon (PA), zirconia Tank (ZRO), corundum tank, agate ball mill tank, vacuum ball mill tank, etc. are optional |

Carrier volume: | 100ml -3000ml |

Ball milling media material: | stainless steel, tungsten carbide ball, agate ball, zirconia ball, corundum ball, nylon ball, PTFE ball, etc. are optional |

Media diameter: | 3/5/10/15/20mm |

Media quality: | 200-1000g |

Grinding method: | dry grinding / wet grinding |

Low temperature cooling treatment: | Yes (additional) |

惰性气体保护处理: Inert gas protection treatment: | Yes |

Net weight: | 92kg |

Size (length, width and height): | 720*480*500mm |

Standard: | CE |

Optional accessories:

1、Optional material of ball mill tank:

2、Special ball mill tank for vacuum/inert gas protection treatment:

Optional volume of ball mill carrier: 100ml (need to be equipped with tank pads) / 250ml / 3000ml (standard)

3、Optional materials for ball milling media:

ball milling media: 3/5/10/15 / 20mm

Optional diameter of Packing specifications of ball milling media: 200g/can 500 g/can 800 g/can 1000 g/can

-

浸入式液氮冷冻研磨仪

-

三维冷冻研磨仪

-

高通量组织研磨仪

-

全自动样品快速研磨仪-24L

-

三维样品研磨仪

-

中通量组织研磨仪

-

全自动样品快速研磨仪-32L

-

三维离心冷冻研磨仪

-

三维离心冷冻研磨仪

-

中通量组织研磨仪

-

全自动样品快速研磨仪-48L

-

高速组织研磨仪

-

全自动样品快速研磨仪-64L

-

高速组织研磨仪

-

超高通量组织研磨仪

-

全自动样品快速研磨仪-96L

-

超高通量组织研磨仪

-

高通量组织研磨仪

-

高通量冷冻混合研磨仪

-

全自动样品快速研磨仪

-

冷冻研磨仪

-

手持式研磨仪

-

中通量研磨仪

-

快速组织破碎研磨仪

-

全自动样品快速研磨仪

-

高速组织研磨仪

-

全自动样品快速研磨仪

-

便携式研磨仪

-

低温组织研磨仪

-

基础款冷冻研磨仪

-

低温组织研磨仪

-

高通量土壤研磨仪

-

高通量组织研磨仪-2018

-

平行研磨仪

-

多样品组织研磨仪-24L

-

多样品组织研磨仪-32L

-

大容量刀式研磨仪

-

刀式研磨仪

-

多样品组织研磨仪-48L

-

多样品组织研磨仪-64L

-

多样品组织研磨仪-96L

-

多样品组织研磨仪-192L

-

全自动样品快速研磨仪-96

-

低温研磨仪

-

全自动样品快速低温研磨仪

-

全自动样品快速研磨仪-32

-

全自动样品快速研磨仪-192

-

多样品组织研磨仪-24

-

多样品组织研磨仪-96

-

多样品组织研磨仪-FEII

-

MINI快速检测研磨仪

-

组织研磨仪

-

迷你金刚研磨仪

-

全自动浸入式液氮冷冻研磨仪

-

冻台冷冻研磨仪

-

切割式研磨仪

-

超离心研磨仪

-

低温&灭活研磨仪

-

真空冷冻研磨仪

-

低温&灭活研磨仪

-

大功率手持式研磨仪

-

塑胶材料检测专用研磨仪

-

全自动低温快速研磨仪

-

全自动样品快速研磨仪

-

迷你研磨仪

-

冷冻研磨仪

-

多样品组织研磨仪

-

便携式研磨仪

-

高效振动盘式研磨仪

-

臼式研磨仪

-

叶绿素A研磨仪

-

水质叶绿素研磨仪

-

高速组织研磨仪KZ-II

-

全自动样品快速研磨仪-24

-

基础款冷冻研磨仪

-

冷冻研磨仪

-

冷冻研磨仪

-

全自动浸入式液氮冷冻研磨仪