Product Description:

The 4LQM-3SP4 high-performance ball mill can grind samples to nanometer level in a short time. The instrument is suitable for grinding (dry or wet grinding) and mixing processing of soft, medium-hard, extremely hard, and brittle samples, and guarantees the grinding The results are repeatable. It can be used in the preparation of physical and chemical analysis, colloidal grinding, new materials and mechanical alloys.

working principle:

When the instrument is started, the motor drives the public sun gear to rotate, and the grinding jar on the sun gear rotates around its own axis. The direction of the grinding jar's rotation is exactly opposite to the direction of the sun gear. The rotation speed ratio of the sun gear and the grinding tank is generally 1:-2.3. When the grinding ball and the grinding jar are operated together, they are affected by the superimposition of the deflection force of the rotation. Under this influence, the grinding ball releases a large amount of kinetic energy. Shattered.

Main advantage:

Suitable for long-term sample preparation and continuous operation

The speed is adjustable, the operation is stable, and the sample can be ground to the fineness of micron level (dry grinding) and nano level (wet grinding).

Automatic reverse operation to prevent sample accumulation

6 different material grinding jars to choose from

Advanced operation interface, simple and convenient

Basic parameters:

Main parameters | Parameter range |

Brand Name: | JXFSTPRP Jingxin |

Product name: | Planetary Grinding Machine |

Model: | 4LQM-3SP4 |

Injection size (different materials): | < 10mm |

Sample size: | < 100nm |

Processing capacity: | 50ml/can |

Processing capacity: | 4x1000ml |

Main disc speed: | 50-400r/min |

Rotation speed of ball mill tank: | 100-800r/min |

Transmission ratio (planetary disc/ball mill tank): | 1:-2 |

Forward and reverse operation: | Yes |

Continuous running time setting: | 00:01:00-99:59:59 |

Pause time setting: | 00:01:00-99:59:59 |

Dangerous emergency stop: | Yes |

Grinding room lighting description: | None |

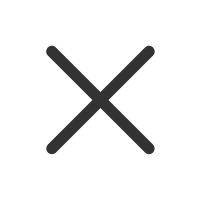

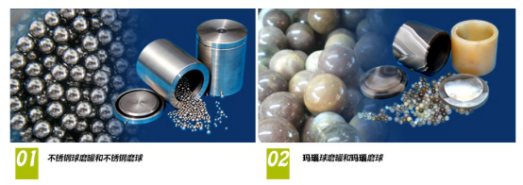

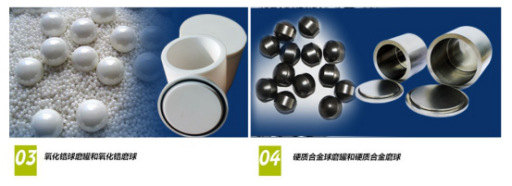

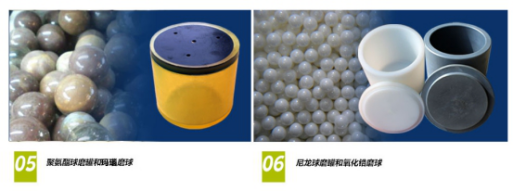

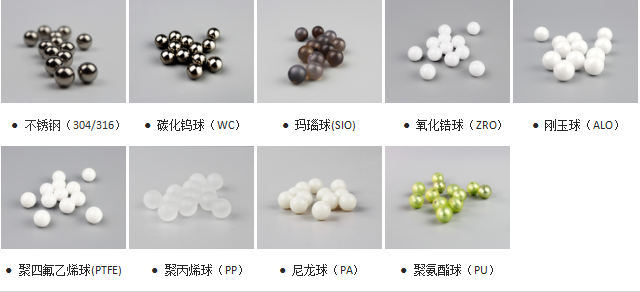

Ball mill carrier material: | stainless steel, agate, zirconia, corundum, tungsten carbide, polyurethane, etc. optional |

Carrier volume: | 00ml -1000ml |

Material of ball milling media: | stainless steel, agate, zirconia, corundum, nylon, polytetrafluoroethylene optional |

Media diameter: | 3/5/10/15/20mm |

Media quality: | 200-1000g |

Grinding method: | dry grinding / wet grinding |

Low temperature cooling treatment: | Yes (additional) |

Inert gas protection treatment: | Yes |

Net weight: | 92kg |

Size (length, width and height): | 720*480*500mm |

Standard: | CE |

Grinding effect diagram:

Different treatment effects:

1、Optional material of ball mill tank:

Optional volume of ball mill carrier: 100ml (need to be equipped with tank pads) / 250ml / 1500ml (standard)

Optional diameter of ball milling media: 3/5/10/15 / 20mm

Packing specifications of ball milling media: 200g/can 500 g/can 800 g/can 1000 g/can