Application of Water Quality COD Automatic Analysis Workstation in Quanzhou Drainage Management Center Station-Shanghai Jingxin

User Profile:

Quanzhou Drainage Center, formerly known as Quanzhou Water Purification Center, is a public institution with full financial appropriation managed by Quanzhou City Administration and is a public welfare institution.

Ⅰ、 Main Responsibilities

1. Undertake the repair, maintenance and management of the four sewage treatment plants in the central urban area (Baozhou, Beifeng, Chengdong, Donghai) supporting the main sewage pipes of the pipe network and the supporting sewage lifting pump stations;

2. Undertake the transformation of the main sewage pipes of the supporting pipeline network of the four sewage treatment plants (Baozhou, Beifeng, Chengdong, Donghai) in the central urban area, and participate in the supporting of the four sewage treatment plants in the central urban area (Baozhou, Beifeng, Chengdong, Donghai) Water quality testing of the main sewage pipes of the pipe network and the four sewage treatment plants in the central urban area;

3. Under the leadership of the competent department, be responsible for the follow-up inspection, evaluation and assessment, monitoring and supervision of the entire operation process of the four sewage treatment plants (Baozhou, Beifeng, Chengdong, Donghai) and the urban sludge incineration disposal in the central urban area. The department provides technical support;

4. Provide technical support for the management of drainage and sewage treatment facilities by the competent authorities.

Purpose:

Shanghai Jingxin Water Quality COD automatic intelligent analysis workstation JX-C7048, conducts test comparison of certified standard products and water samples of the Ministry of Environmental Protection, and verifies whether the instrument meets the daily water sample testing needs of users.

Experimental steps:

1. Configure potassium dichromate (high and low concentration), ferrous ammonium sulfate (high and low concentration), sulfuric acid- Silver sulfate, test ferrous spirit indicator, mercury sulfate solution. Prepare the corresponding quality control standard solution.

2. Turn on the condensate machine, air compressor, and power on the instrument. Pipette the corresponding control or sample into the sample cup and add the rotor. Edit the corresponding sample information on the software.

3. Insert the reagent pipeline into the corresponding reagent, turn on the rinse, click the start button on the software, and the instrument starts to run automatically.

4. After the sample measurement is completed, export the data, take out the cup, and clean the cup.

5. Turn off the power of the instrument, turn off the condensate machine and the air compressor.

Instrument performance test:

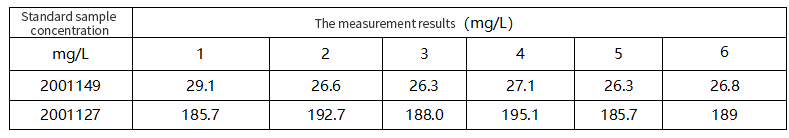

Standard Test:

Test 2001149 and 2001127 standard samples respectively, the test data are as follows

The test data all meet the quality control requirements of standard products.

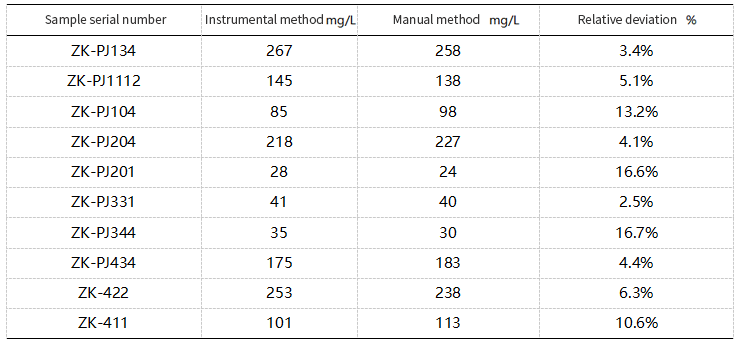

Instrument and manual comparison:

Take 10 water samples respectively, follow the HJ828-2017 standard operating steps, perform manual operation and on-board operation, compare the obtained experimental data, and calculate the percentage of deviation between the two.

According to the experimental data, the results show that both the instrument method test results and the manual method test results are less than 20%, and JX-C7048 meets the needs of practical work.