Model:JX-GN150

Brand:Shanghai Jingxin

Specifications :Set

Introduction:The vertical eccentric pendulum shaft is adopted. When the motor is running at high speed, the vibrating platform eccentrically swings, generating a certain centrifugal force and inertial force moving in the direction of rotation,......

Main principle:

The vertical eccentric pendulum shaft is adopted. When the motor is running at high speed, the vibrating platform eccentrically swings, generating a certain centrifugal force and inertial force moving in the direction of rotation, driving the three tanks on the platform to perform three-dimensional movement up and down, left and right, and back and forth, and the grinding balls in the tank correspond to Do three-dimensional movement, high-speed impact on the tank wall to grind the sample, and the heat generation ratio is low, the milling energy input is 2-3 times higher than the traditional planetary two-dimensional movement.

The sample realizes mechanical alloying in a very short time to form nano ultrafine powder or amorphous material.

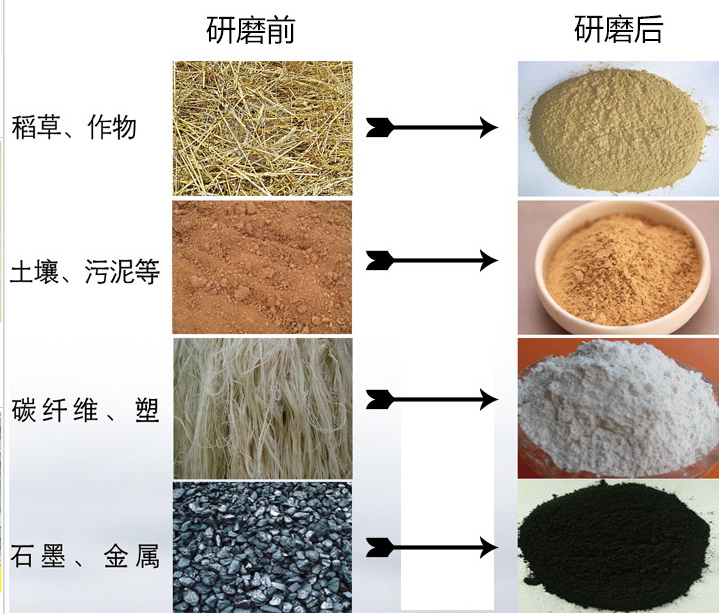

Application range:

Grinding of trace and small samples in laboratories of major universities and research laboratories in biology, chemical industry, materials, construction, environment, geology and mining, pharmaceuticals and other industries;

Mechanical alloying and new material development in electronics and materials industries;

Various industries, dry and wet ball milling or mixing various solids, suspensions and pastes with different particle sizes and materials.

Design Features:

○Vertical eccentric shaft design, three-dimensional movement of the tank

○It can grind three different materials at the same time, with good synchronization and repeatability

○The instrument has a stable center of gravity and a double-layer design to prevent the phenomenon of "off-tracking" during the grinding process

○Tensile spring balance system to prevent damage to the vibration platform caused by huge impact

○Asynchronous motor to ensure continuous operation of the instrument for up to 72 hours

○The tank body is sealed, which can realize dry and wet grinding and mixing

○The tank can be immersed in liquid nitrogen to realize low-temperature grinding

technical parameter:

Main parameters | Parameter range |

Tank specifications: | 50ml, 80ml (customizable) |

Large filling capacity per tank: | two-thirds of the volume of the ball mill tank |

Large feed size: | <25px |

Discharge particle size: | as small as 0.1μm |

Vibration frequency: | 1200 times/min |

Tank amplitude: | vertical direction: 50mm; front and rear direction: 18mm |

Power parameters: | 220V 50Hz |

Experimental case

1. Description:

(1) Application field: environment;

(2) Materials/raw materials: soil, pebbles;

(3) The particle size of the feed material: 1mm;

(4) Feeding amount: 500g;

(5) Material properties: brittle;

(6) Customer requirements: 50μm;

(7) Post-sequence analysis: particle size analysis.

2. Scheme:

(1) Equipment (instrument) selection: JXGS-1A, soil grinder;

(2) Jar and ball configuration: agate jar with agate ball;

(3) Operating parameters: 500 revolutions per minute of autorotation, alternating forward and reverse rotation after 30 minutes;

(4) Grinding time: 1 hour;

(5) Results (recommendation): JXGS-1A can be used to grind the soil;

(6) Grinding result: 100%<50μm.