Experimental operation of frozen grinder JXFSTPRP-CL on grinding fresh pigskin samples | Shanghai Jingxin

Ⅰ、Customer-related introduction, research group, research direction introduction

Frontage Pharma is an all-round integrated pharmaceutical R&D contract research organization (CRO), which can provide comprehensive and scientifically based analytical research and development services from drug discovery to development, and is committed to providing high-quality services to pharmaceutical companies. Frontage Pharma provides a full range of product development services for generic and innovative drug companies to support IND (Clinical New Drug Application), NDA (New Drug Application), ANDA (Generic Drug) and 505(b)(2) registration applications . We work closely with our clients to ensure a deep understanding of their drug development goals in order to provide flexible solutions to meet each client's needs; we follow rigorous science, technology and quality systems to ensure high quality and compliance for each project . From new drug feasibility studies to clinical studies, Frontage has helped clients advance hundreds of compounds from product development to commercialization.

Ⅱ、Purpose

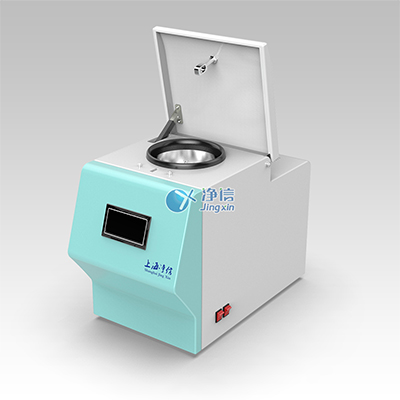

The fresh pigskin samples are ground and pulverized. Since the customer samples are tough and difficult to handle, the customer chooses Shanghai Jingxin JXFSTPRP freezer grinder for sample pretreatment.

Ⅲ、 Experimental site, experimental materials and equipment

Suzhou Fangda New Drug Development Co., Ltd. laboratory, JXFSTPRP-CL freezer grinder, steel tank adapter, several steel balls, liquid nitrogen, scissors and other test equipment;

Ⅳ、Experimental procedure

1. Put the processed samples into the steel tank adapter;

2. Immerse the stainless steel tank in liquid nitrogen for a few minutes;

3. Put the soaked steel can into the designated adapter position of the machine;

4. Start the program after setting the corresponding parameters, and take out the sample after the grinding is completed;

5. Take out the ground samples and wait for the next step of testing;

Ⅴ、Experimental results

By testing and analyzing the ground samples, it fully meets the customer's requirements;

Ⅵ、Precautions

1. During the grinding process, the sample should be cut into small pieces. Due to the strong toughness of the pig skin, the conditions must be met in the liquid nitrogen soaking solution, so that the grinding effect will be more sufficient;

2. During the operation, be sure to pay attention to the safety of the operation process, liquid nitrogen can easily cause danger;

- Home

- About us

-

Product

-

Grinder for scientific research

Grinder for scientific research

- Enhanced multi-sample tissue grinder

- Enhanced automatic sample rapid grinder

- Enhanced cryomill

- Multi-sample tissue grinding machine

- Automatic sample rapid grinder

- Cryogenic tissue grinder

- Three-dimensional motion grinder

- Single cell suspension preparation instrument

- Freezer tissue grinder

- Liquid nitrogen Cryogenic Grinder

- High Throughput Tissue Grinder

-

Grinder for analysis and detection

Grinder for analysis and detection

- Hair drug detector

- Handheld Grinder

- QuEChERS pre-processing all-in-one machine

- Soil/High Energy Planetary Grinder

- Hammer cyclone mill

- Knife grinder

- Multifunctional/Automatic Homogenizer

- Three dimensional vibrating ball mill

- Chlorophyll/soil A grinder

- Mortar grinder

- High-efficiency vibrating disc grinder

- Jaw grinder

- Flap homogenizer

- Bead-milling tissue grinder

- Special grinder for African swine fever

- Three-dimensional mixing instrument

- Miniature bead mill

- Forensic bone and tooth ball mill

- Percussion grinder

- Rotary splitter

-

General Instruments

General Instruments

- Ultrasonic cell disruptor

- Ultrasonic equipment

- In situ hybridization instrument/n instrument/crosslinking

- instrument Dry type thermostat/constant temperature mixer

- Vortex mixer/nitrogen purging instrument

- PCR instrument/membrane sealing instrument Snow ice

- Microplate constant temperature shaking incubator

- Orbital shaker/micro centrifuge

- Inoculation loop sterilization/indicator incubator

- Solid phase extraction device/low temperature thermostat

- Snow ice maker/viscometer/lyophilizer

- Flip oscillator

- Soil drying box/humidity box

-

Xiaomei Ultrasound Series

Xiaomei Ultrasound Series

-

Vibrating sieve shakers

Vibrating sieve shakers

-

Foreign distribution products

Foreign distribution products

-

Grinder for scientific research

- Customers

- News

- Videos

- Case

- Cantact